Introduction: Why our ISOBUS solution deserves your attention

ISOBUS (ISO 11783) is a global standard for communication between implements and tractors, across all manufacturers: it is the "universal language" developed to ensure compatibility and simplify controls.

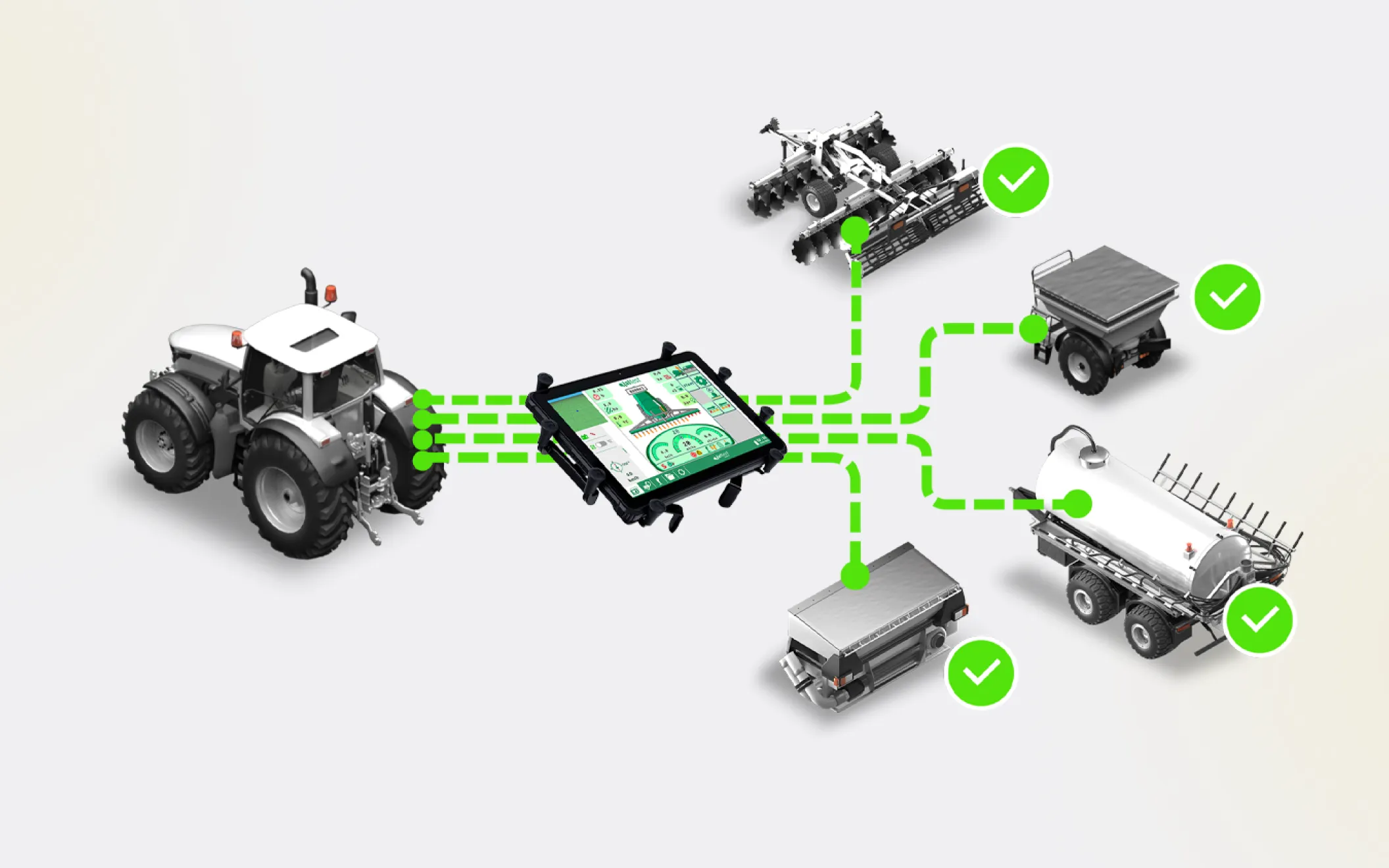

At FieldBee, we have adopted the ISOBUS standard through our ISOBUS Kit, designed to make precision farming simpler and more effective.

With it, our farmers can benefit from:

- Universal Terminal (UT): Control any certified ISOBUS implement directly from the FieldBee tablet – one device for all machines.

- Task Controller (TC): Automate Section Control (TC-SC) and Variable Rate Applications (TC-GEO), saving inputs and increasing yields.

- Seamless integration: Easy installation, full compatibility with the FieldBee automatic guidance system, and operation through a single display.

This guide will walk you through the FieldBee ISOBUS Kit, how it works in practice, and how to upgrade your farming practices with ISOBUS.

1. ISOBUS: fundamental concepts that every farmer should know

What is ISOBUS?

ISOBUS is a CAN-based communication standard designed to ensure compatibility between implements from different brands and a wide range of control hardware.

The result? Farmers can operate implements from multiple manufacturers using a single display — avoiding the need for multiple monitors and eliminating confusing or incomplete interfaces.

Key ISOBUS Components

To better understand how ISOBUS works in practice, here are its main components and the value they bring:

- Virtual/Universal Terminal (VT/UT): One simple in-cab tablet to control all ISOBUS implements — no more juggling multiple monitors.

- Task Controller – Base (TC-BAS): Automatically records job data (e.g., worked area), making reporting and compliance effortless.

- Task Controller – Section Control (TC-SC): Switches implement sections (e.g., sprayer nozzles) on and off automatically — reducing overlaps, saving inputs, and protecting the environment.

- Task Controller – Geo (TC-GEO): Delivers variable-rate applications with precision, applying exactly what’s needed, where it’s needed.

- Tractor ECU (TECU): Shares key tractor data (e.g., speed, PTO) with implements, ensuring smooth, synchronized performance.

- Auxiliary Controls (AUX-N): Handy physical buttons or joysticks for instant actions — giving farmers fast, intuitive control.

Note: Not all combinations are always possible — please consult your dealer for proper verification.

2. ISOBUS in action

ISOBUS brings clear advantages across all farming operations — from sowing to spraying to harvesting. Here’s how it delivers value in practice:

? Sowing & Fertilisation

- Section Control: Avoids overlaps and gaps, ensuring every part of the field is covered correctly.

- TC-GEO: Applies seeds and fertilisers at variable rates, cutting waste and boosting efficiency.

? Spraying

- Precision Control: Manage sections down to nozzle and boom level, reducing drift and saving inputs.

- TC-GEO: Enables variable-rate spraying, targeting only where pressure is higher.

? Harvesting

- Seamless Monitoring: Track machine performance and field data directly on the FieldBee tablet (UT).

- TC-BAS: Records harvested areas automatically and integrates with your farm management software.

- Section Control (TC-SC): Operates chaff spreaders and headers with precision, eliminating overlaps and protecting crop quality.

3. FieldBee ISOBUS Kit: Your tool for smarter farming

The FieldBee ISOBUS Kit brings full professional ISOBUS functionality to your tractor — without the need for extra stand-alone terminals.

What’s included:

- Wiring & connectors: Add ISOBUS ports to your tractor with ready-to-install hardware.

- Software licenses: UT and TC-BAS included, with optional upgrade to TC-GEO for variable-rate applications.

- Seamless integration: All functions run on the FieldBee Tablet, combining automatic steering and implement control on one screen (swap or split-screen).

- Cost-effective: Quick installation and no need for an external terminal — unless specifically requested by the customer.

4. How to set up and use ISOBUS with FieldBee: a step-by-step workflow

The kit is easy to install and use. It guides you from setup to data analysis:

- Install the kit

Fit the supplied ISOBUS wiring harness and rear ISOBUS plug. No extra cables or shields required. - Connect the implement

Plug in your AEF-certified ISOBUS implement.

The FieldBee Tablet automatically detects it via UT.

If the implement supports Section Control or Variable Rate, those functions appear in the manufacturer’s native interface. - Plan and upload prescription maps (optional)

Import your field maps (GeoTIFF or ISOXML) for variable-rate work. - Operate in the field

Use the UT to monitor and control the implement.

TC-SC switches sections automatically based on position.

For variable-rate tasks, TC-GEO adjusts output in real time according to the map. - Record and analyse

Use TC-BAS to export task data—ideal for performance review, reporting, and next-season planning.

5. Testing tips: Getting ISOBUS to work smoothly

- Check compatibility: Confirm with your dealer, the implement manufacturer’s specs, or the AEF ISOBUS database.

- Start simple: Begin with a single task, like spraying, before moving on to variable-rate operations.

- Practice Section Control: Test in an open field to avoid overlaps and get familiar with the controls.

- Keep records: Use TC-BAS to log your work and easily meet compliance requirements.

6. Benefits of ISOBUS with FieldBee

- Efficiency: One device, one interface — no duplicate monitors or controls.

- Precision: Targeted applications with fewer overlaps and variable-rate dosing.

- Data-driven: Every job is recorded for planning, reporting, and compliance.

- Data integration: possibility to integrate ISOBUS data into FMIS platforms (such as xFarm or other software), closing the loop from field to office.

- Future-proof: As tractors and implements evolve, ISOBUS ensures lasting compatibility.

- Sustainability: Less input waste and optimized use of resources, reducing environmental impact.

- Ease of use: Simple installation and intuitive operation — no need for extra training or complex setup.

7. In short, ISOBUS with FieldBee means:

- Simplification: One terminal for all implements — less clutter, more comfort in the cab.

- Smarter inputs: Section Control and variable-rate dosing cut waste and boost yields.

- Harvest efficiency: Yield data and section logic make combine passes smoother and crop quality higher.

- Data & compliance: TC-BAS records every job automatically — no more manual spreadsheets.

- Compliance & reporting: ISOBUS data is ready for audits, certifications, and traceability requirements (essential for grants or CAP support).

- Comfort & reduced stress: one single terminal lowers the risk of mistakes, fatigue, and confusion in the cab.

- Wide compatibility: Works seamlessly with implements from different brands, today and tomorrow.

- Sustainability: Optimised applications mean fewer inputs, lower costs, and reduced environmental impact.

- Ease of adoption: Quick installation and intuitive interface — no extra training required.

- Future upgrades: Ready for new ISOBUS functions (AUX-N, TIM, etc.), so the system grows with your farm.

- Data connectivity: possibility to integrate ISOBUS data into FMIS platforms (such as xFarm or other software), closing the loop from field to office.

Conclusions

ISOBUS isn’t just a buzzword — it’s a proven standard that brings precision, clarity, and efficiency to everyday farming. With the FieldBee ISOBUS Kit, you put this power directly on your tablet, gaining smarter and simpler control over spraying, planting, harvesting, and long-term farm planning — fully compatible today and ready for the future.